Our Products

Worm Gear

Strength. Reliability. Flexibility.

What is a Worm Gear?

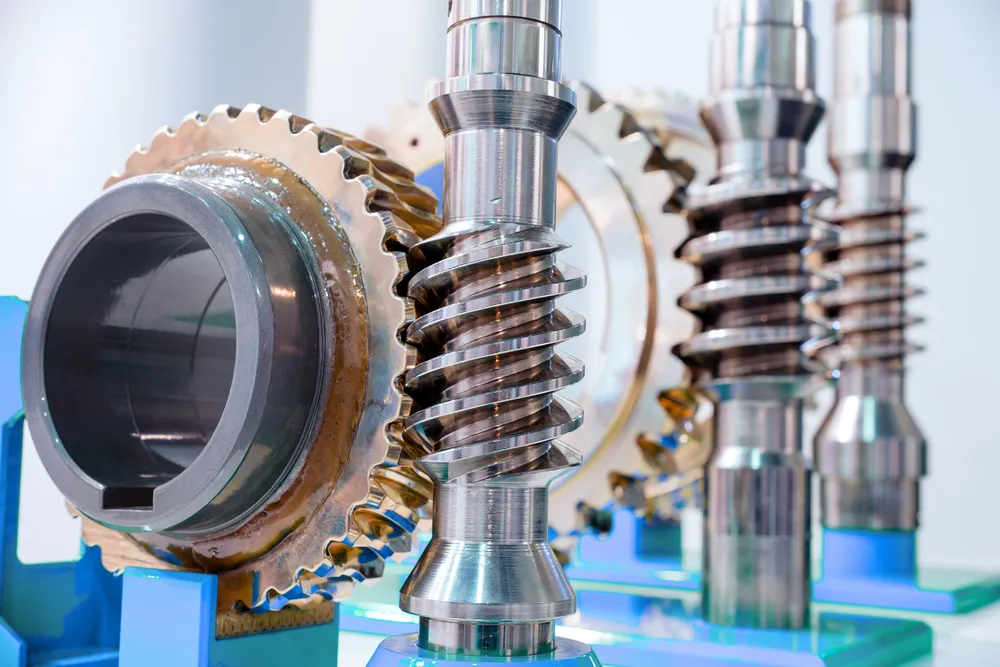

A worm gear is a type of gear system that consists of a cylindrical gear with helical teeth, called a worm, and a toothed wheel, known as the worm wheel or worm gear. The worm gear has a screw-like thread that meshes with the teeth of the worm. The configuration of a worm gear enables motion and power transmission between non-parallel and perpendicular shafts.

The unique feature of a worm gear is its ability to provide high gear reduction ratios, which means that for each rotation of the worm, the worm wheel rotates by a smaller amount. This feature makes worm gears ideal for applications where high torque and low-speed operation are required.

How Worm Gears are Made

Gear Blank Preparation

The process starts with preparing the gear blank, which is the initial raw material for the worm gear. The gear blank is usually made from a suitable metal or alloy, such as steel, bronze, or cast iron.

Cutting the Worm

The next step involves cutting the helical thread of the worm. This is typically done using specialized machining processes such as hobbing or milling.

Heat Treatment

After the worm is cut, heat treatment is often applied to enhance its hardness, strength, and wear resistance.

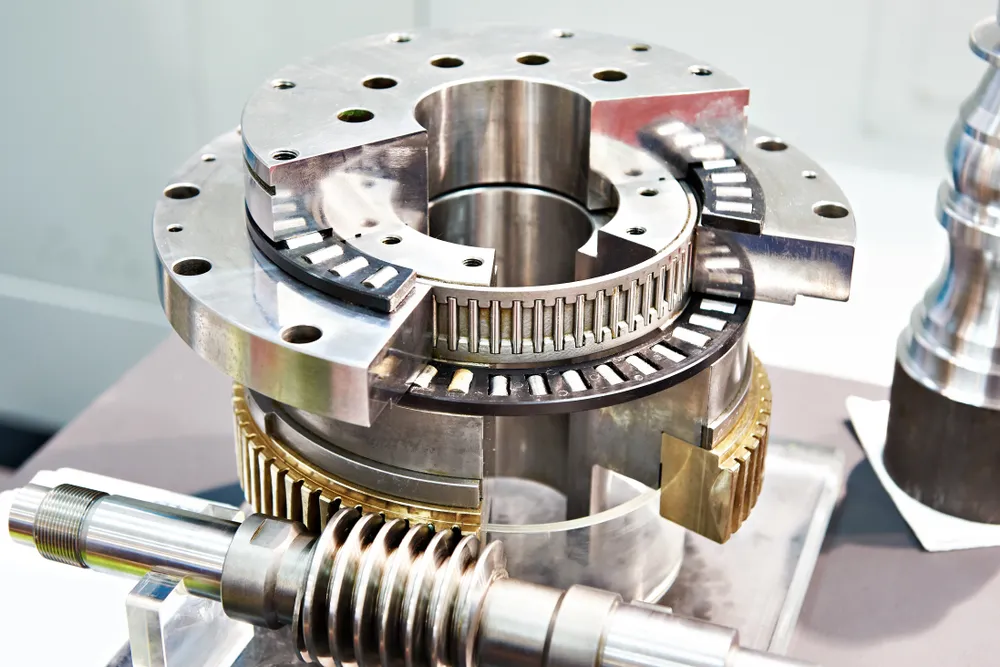

Machining the Worm Wheel

The worm wheel, or the toothed wheel that meshes with the worm, is typically machined separately from the worm. Machining processes like hobbing, milling, or shaping are employed to create the teeth on the worm wheel.

Finishing Operations

After the teeth of the worm and worm wheel are formed, various finishing operations are performed to ensure the required accuracy and surface quality.

Assembly

Once the worm and worm wheel is individually produced, they are assembled together, with appropriate bearings or bushings, to create the complete worm gear system.

Types of Worm Gears

Non-throated Worm Gear

This is the most basic type of worm gear. It has a cylindrical worm with straight or helical teeth that engage with a cylindrical worm wheel. Non-throated worm gears typically provide lower efficiency and have a higher coefficient of friction.

Single Enveloping Worm Gear

In this type, the worm has a concave shape, and the worm wheel has a corresponding convex shape. The teeth engage in a manner that allows more contact area and improved load distribution. Single enveloping worm gears offer higher efficiency and load-carrying capacity compared to non-throated worm gears.

Double Enveloping Worm Gear

The double enveloping worm gear has a worm with a concave shape and a worm wheel with a double convex shape. The teeth engagement occurs on both sides of the worm gear, resulting in enhanced load capacity and efficiency. Double enveloping worm gears are known for their high precision and torque transmission capabilities.

Tangential or Duplex Worm Gear

In a tangential or duplex worm gear, two worms are placed side by side on the same shaft, engaging with a common worm wheel. This configuration increases load capacity, distributes the load between the worms, and provides improved torque transmission.

Hourglass Worm Gear

Hourglass worm gears have a unique hourglass shape. The worm has a wider middle section, and the worm wheel has a corresponding shape. This design allows for increased tooth engagement and better load distribution, leading to higher efficiency and load capacity.

Right-Angle Worm Gear

Right-angle worm gears are designed to transmit motion at a 90-degree angle. They have a worm that meshes with a worm wheel positioned at a right angle to the worm. These gears are commonly used in applications where the input and output shafts need to be perpendicular.

Worm Gear for Sale

As a worm gear manufacturer, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

Worm Gear Lubrication

Proper lubrication is crucial for the efficient and reliable operation of worm gears. Here are some important considerations for worm gear lubrication:

Lubricant Selection

Selecting the right lubricant is vital. Worm gears typically require lubricants with high viscosity to provide sufficient film thickness and protect against wear. It is recommended to use lubricants specifically formulated for worm gears, as they are designed to handle the unique sliding and rolling motion of the gears. These lubricants often have additives to enhance extreme pressure (EP) and anti-wear properties.

Viscosity

The viscosity of the lubricant is essential for proper lubrication. It should be chosen based on the operating temperature and load conditions. The lubricant’s viscosity should be able to form an adequate film to separate the contacting surfaces and prevent metal-to-metal contact.

Lubrication Method

Worm gears can be lubricated through various methods, such as oil bath lubrication or grease lubrication. Oil bath lubrication involves partially submerging the worm gear in an oil reservoir, allowing the gear to pick up lubricant as it rotates. Grease lubrication involves applying a consistent layer of grease to the gear teeth.

Lubrication Interval

Establishing a regular lubrication interval is important to maintain proper lubrication levels. The interval depends on factors such as the operating conditions, load, and temperature. It is recommended to follow the manufacturer’s guidelines or consult with lubrication experts to determine the appropriate lubrication frequency.

Custom Gear

We specialize in manufacturing custom gears for OEMs. Whether you need custom gear, or some engineering assistance to perfect your design, our team is ready to help.

Our capabilities include helical and spur gears, custom cut or precision ground to perfection. Other gear types include custom pump gears, bevel gears and worm gears ranging in diameter from a fraction of an inch to three feet. We not only manufacture gears, but also splines, sprockets, shafts, components and spare parts.

We want to be your custom gear supplier. Let us bring to you 20+ years of collective experience, and custom gear manufacturing you can rely on.

Our diverse product offering can meet a variety of size and volume needs, including complex part combinations and tight tolerances. We can take care of your needs, from gear grinding to complete turnkey assemblies, everything is custom-made to our customers’ exact specifications, ensuring a perfect fit for their application every time. With multiple manufacturing divisions and locations, we are large enough to handle high volumes, yet small enough to provide each customer with exceptional, personalized service.